How AI is Transforming Apparel Manufacturing

Artificial intelligence is revolutionizing production processes and supply chain management

Michael Chen

Chief Technology Officer

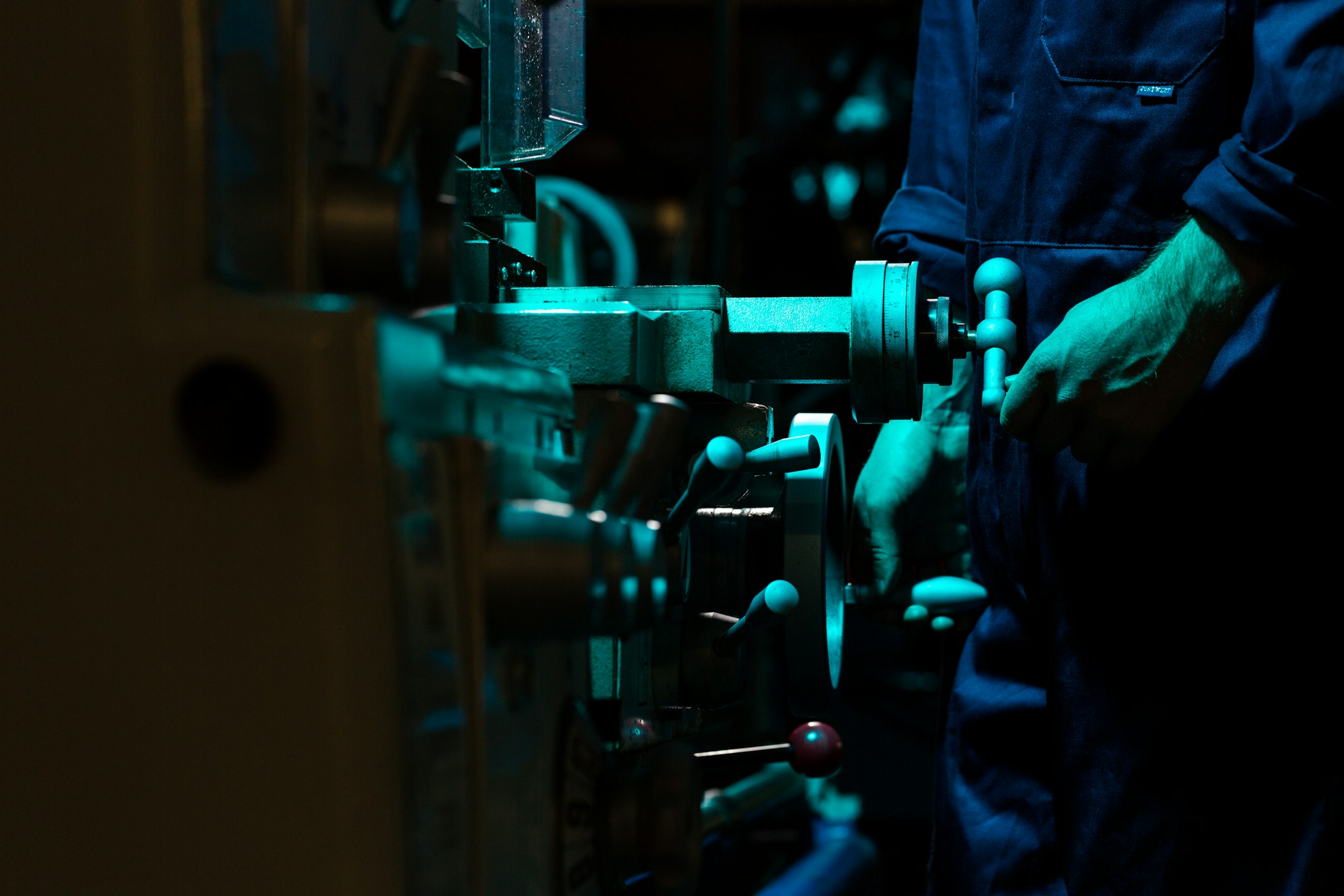

The apparel manufacturing industry is undergoing a profound transformation driven by artificial intelligence. Traditional manufacturing methods, characterized by labor-intensive processes and limited automation, are giving way to smart factories where AI orchestrates everything from cutting and sewing to quality control and logistics.

At the forefront of this revolution are companies like Anatar, which is developing AI-enabled systems for real-time orchestration and optimization of apparel production. These systems represent a fundamental shift in how clothing is made, addressing longstanding challenges in the industry.

Real-Time Production Optimization

One of the most significant applications of AI in apparel manufacturing is real-time production optimization. AI systems can analyze thousands of variables simultaneously to determine the most efficient production routing, material usage, and machine settings.

"Traditional manufacturing relies on static production plans that can't adapt to changing conditions," explains Michael Chen, CTO at Anatar. "Our Loom Flow system uses machine learning to dynamically route production across factory lines based on real-time demand signals, equipment availability, and material constraints."

This dynamic approach results in significantly higher throughput, reduced waste, and faster response to market demands—all critical factors in an industry where timing and efficiency directly impact profitability.

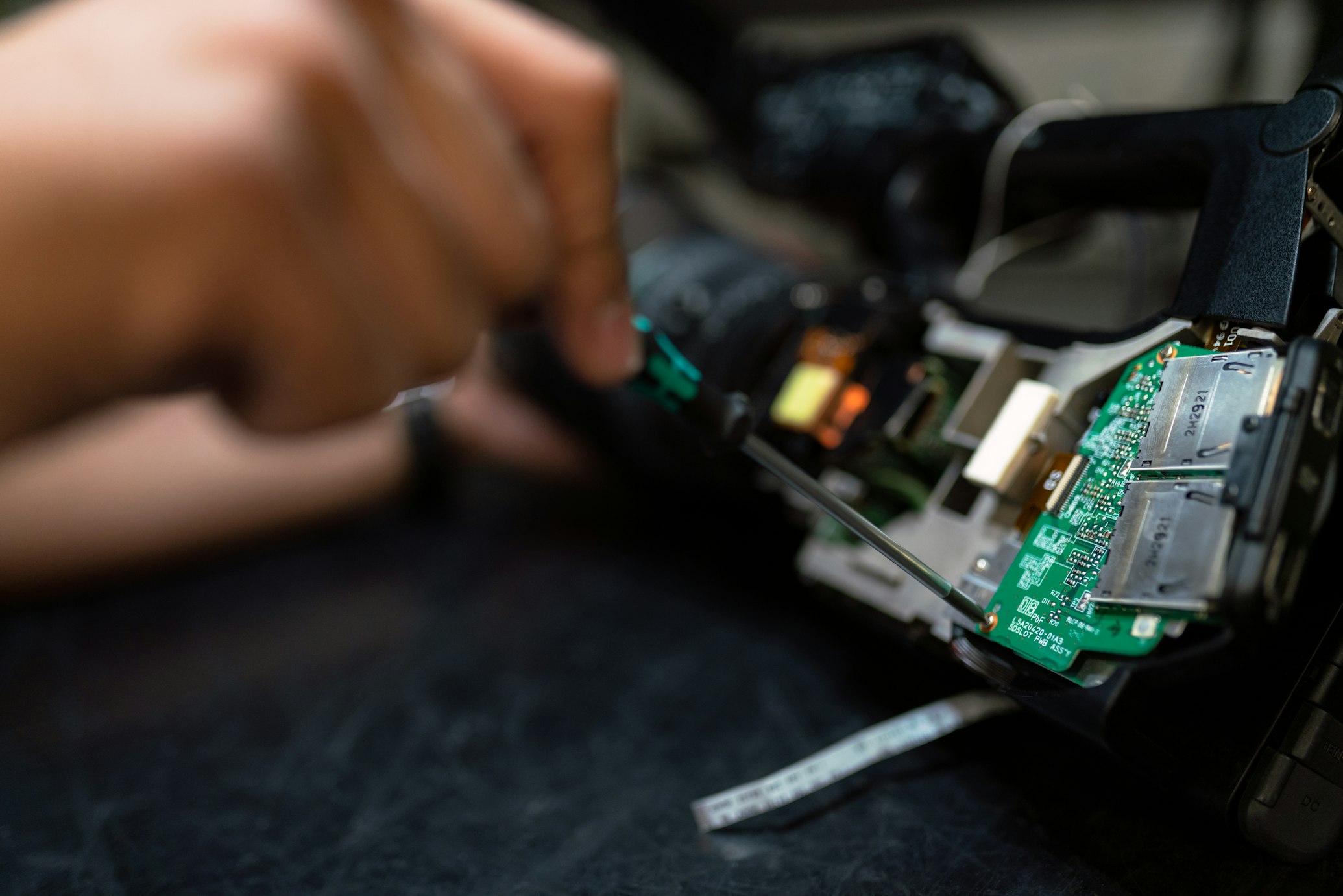

Quality Control Revolution

Quality control has traditionally been a manual, sample-based process in apparel manufacturing. AI is changing this paradigm by enabling 100% inspection through computer vision systems.

"Computer vision can detect defects that human inspectors might miss, and it can do so consistently across every item produced," says Chen. "This not only improves quality but also generates valuable data that feeds back into the production process to prevent future defects."

These systems can identify issues ranging from stitching errors and fabric flaws to color inconsistencies, all at speeds impossible for human inspectors to match.

Supply Chain Visibility and Traceability

Perhaps the most transformative aspect of AI in apparel manufacturing is its ability to create unprecedented supply chain visibility. With 97% of U.S. apparel imported, supply chains are typically fragmented across multiple countries with limited visibility.

AI-powered systems like Anatar's Loom Chain provide traceability from raw materials to finished products. This visibility is increasingly important for brands concerned about sustainability, ethical production, and supply chain resilience.

"Consumers and regulators are demanding more transparency about how and where products are made," notes Kaia Rhodes, Founder and CEO of Anatar. "Our technology provides that visibility while also enabling more efficient, responsive supply chains."

The Future: Closed-Loop Manufacturing

The ultimate promise of AI in apparel manufacturing is closed-loop systems that continuously improve based on data from every stage of the product lifecycle.

"We're building systems that learn from every garment produced, every customer interaction, and every return," explains Rhodes. "This creates a virtuous cycle where production becomes increasingly efficient and products become increasingly aligned with customer preferences."

As these technologies mature and scale, they have the potential to reshape not just how apparel is made, but where it's made. By dramatically reducing the labor component of production costs, AI and automation are making it economically viable to reshore manufacturing to countries like the United States.

For an industry that has seen 90% of its jobs move offshore over the past few decades, this represents not just a technological revolution, but potentially an economic one as well.